Product Description:

The Conveyor Belt Vulcanizing Equipment is a state-of-the-art Portable Belt Vulcanizing Device designed to meet the rigorous demands of rubber conveyor belt maintenance and repair. This advanced piece of machinery is engineered to provide reliable, efficient, and precise splicing solutions, making it an indispensable tool for industries that rely heavily on conveyor belt systems. Whether you are working in mining, manufacturing, logistics, or any other sector where conveyor belts play a crucial role, this Rubber Conveyor Belt Vulcanizer offers unparalleled performance and convenience.

One of the standout features of this Mechanical Conveyor Belt Splicer is its sophisticated digital temperature and pressure control system. This digital control system allows operators to set and monitor the vulcanizing conditions with exceptional accuracy, ensuring that the rubber belts are spliced under optimal parameters. By maintaining consistent temperature and pressure throughout the vulcanizing process, the device guarantees strong, durable bonds that significantly extend the lifespan of conveyor belts and reduce downtime.

The heating mechanism of this vulcanizing equipment utilizes electric heating plates, which provide uniform and rapid heat distribution across the splicing area. The electric heating plates are designed to reach temperatures within a wide range of 0-300°C, accommodating various types of rubber compounds and thicknesses. This temperature range offers flexibility to handle different vulcanizing jobs, from light repairs to heavy-duty splicing, making the equipment versatile for a broad spectrum of conveyor belt materials and applications.

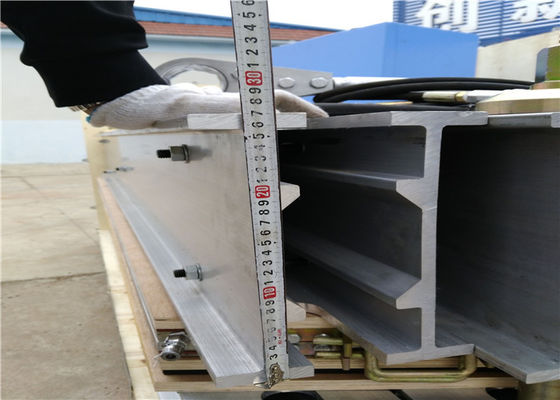

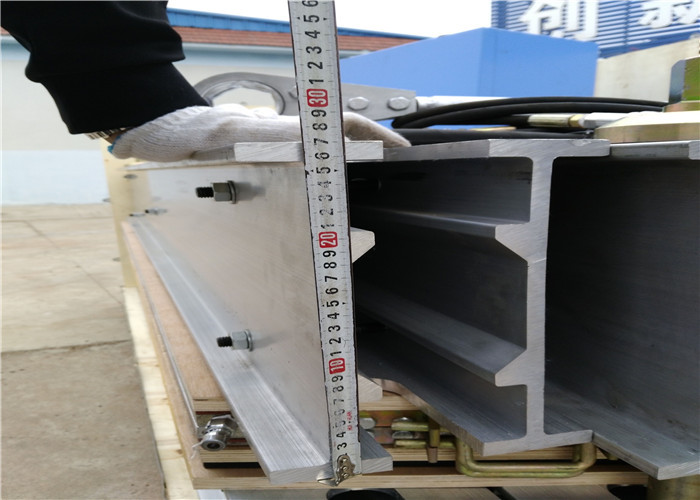

Durability and lightweight construction are achieved through the use of high-quality aluminium alloy materials in the build of this Portable Belt Vulcanizing Device. Aluminium alloy not only contributes to the device’s structural strength but also enhances heat conduction and reduces overall weight, making it easier to handle and operate. The robust construction ensures the equipment can withstand the harsh conditions often encountered in industrial environments, providing long-lasting service and minimal maintenance requirements.

Portability is a key advantage of this Rubber Conveyor Belt Vulcanizer. Equipped with sturdy wheels, the device can be easily moved across different work sites or production lines without the need for heavy lifting or disassembly. This mobile design enables quick deployment and repositioning, which is critical for on-site repairs and emergency maintenance tasks. The mobility feature saves time and labor costs, allowing maintenance teams to respond swiftly to conveyor belt issues and maintain continuous production flow.

In addition to its technical capabilities, this Mechanical Conveyor Belt Splicer is user-friendly, with an intuitive interface that simplifies operation for technicians and engineers. The digital controls provide clear feedback and enable precise adjustment of temperature and pressure settings, reducing the risk of errors and improving the quality of splices. Safety features are incorporated to protect operators during the heating and vulcanizing process, ensuring compliance with industrial safety standards.

Overall, the Conveyor Belt Vulcanizing Equipment represents a perfect blend of advanced technology, portability, and durable construction. Its digital temperature and pressure control system, electric heating plates, aluminium alloy material, and mobile design with wheels make it a superior choice for any facility requiring efficient conveyor belt maintenance. By investing in this Portable Belt Vulcanizing Device, businesses can enhance their operational efficiency, reduce conveyor belt downtime, and improve the reliability of their material handling systems.

Whether you need a reliable Rubber Conveyor Belt Vulcanizer or a versatile Mechanical Conveyor Belt Splicer, this equipment delivers outstanding performance and value. It is engineered to meet the highest industry standards, ensuring that every splice is executed with precision and durability. With the ability to operate within a temperature range of 0-300°C and the convenience of mobility, this vulcanizing equipment is the ultimate solution for maintaining conveyor belt integrity and optimizing production processes.

Features:

-

Product Name: Conveyor Belt Vulcanizing Equipment

-

Control System: Digital Temperature and Pressure Control for precise operation

-

Temperature Range: 0-300°C, suitable for various vulcanizing requirements

-

Operating Temperature: 0-200℃ for effective vulcanizing process

-

Portability: Mobile with wheels for easy transportation and maneuverability

-

Material: Durable Aluminium Alloy construction for long-lasting performance

-

Ideal for use as a Belt Seam Vulcanizing Machine and Rubber Conveyor Belt Vulcanizer

-

Efficient Belt Seam Vulcanizing Machine designed for reliable conveyor belt repairs

Technical Parameters:

|

Portability

|

Mobile With Wheels

|

|

Material

|

Aluminium Alloy

|

|

Control System

|

Digital Temperature And Pressure Control

|

|

Heating Type

|

Electric Heating Plates

|

|

Temperature Range

|

0-300°C

|

|

Operating Temperature

|

0-200℃

|

Applications:

The Automatic Conveyor Belt Vulcanizer is an essential piece of equipment designed for the seamless repair and maintenance of conveyor belts across various industries. Featuring a temperature range of 0-300°C, this Rubber Conveyor Belt Vulcanizer utilizes advanced electric heating plates to ensure uniform heating and precise temperature control, crucial for effective vulcanization processes. Its aluminium alloy construction guarantees durability while maintaining a lightweight structure, making it highly efficient and reliable for extended use.

One of the remarkable attributes of this Automatic Conveyor Belt Vulcanizer is its portability. Equipped with wheels, the device can be easily transported to different locations within a facility or even to remote job sites. This mobility significantly reduces downtime and enhances operational efficiency, especially in large-scale industrial setups where conveyor belts are extensive and spread out over vast areas.

This equipment is widely used in industries such as mining, manufacturing, logistics, and construction where conveyor belts are indispensable for material handling. The Automatic Conveyor Belt Vulcanizer is particularly suitable for applications involving rubber conveyor belts, enabling quick on-site repairs without the need for belt removal or sending it to an off-site repair center. This feature helps in minimizing production interruptions and maintaining continuous workflow.

Additionally, the vulcanizing equipment is ideal for situations requiring precise temperature control ranging from 0 to 200℃ for delicate repairs or up to 300℃ for more demanding vulcanization tasks. The electric heating plates provide consistent heat distribution, ensuring that the rubber vulcanization process is effective, resulting in strong, durable belt joints that can withstand heavy loads and harsh working conditions.

In summary, the Automatic Conveyor Belt Vulcanizer is perfect for on-site conveyor belt maintenance and repair scenarios where portability, temperature accuracy, and material durability are critical. Its aluminium alloy build, electric heating plates, and temperature flexibility make it a versatile tool for industries relying heavily on conveyor belt systems. Whether dealing with routine maintenance or emergency repairs, this Rubber Conveyor Belt Vulcanizer delivers reliable performance to keep conveyor systems running smoothly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!