Product Description:

The Conveyor Belt Vulcanizing Equipment is a state-of-the-art solution designed specifically for the efficient and reliable splicing of rubber conveyor belts in various industrial applications. This advanced machine, often referred to as a Rubber Conveyor Belt Vulcanizer, is engineered to provide precise control and consistent results, making it an indispensable tool for maintenance teams and production facilities that rely heavily on conveyor systems.

One of the standout features of this Industrial Belt Vulcanizing Equipment is its sophisticated digital temperature and pressure control system. This control system ensures that operators can accurately set and monitor the vulcanizing process parameters, which is critical for achieving optimal bond strength and durability. The digital interface allows for easy adjustments and real-time feedback, significantly reducing the chances of errors and enhancing the overall efficiency of the splicing operation.

Portability is a key consideration for users who need to perform vulcanizing tasks at different locations within a plant or across multiple sites. To address this need, the Conveyor Belt Vulcanizing Equipment is designed to be mobile, equipped with sturdy wheels that facilitate easy transportation and positioning. This mobility feature not only saves time but also reduces the physical strain on operators, enabling quick setup and minimizing downtime during maintenance.

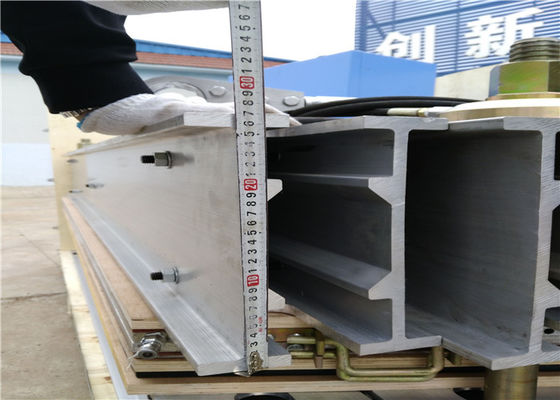

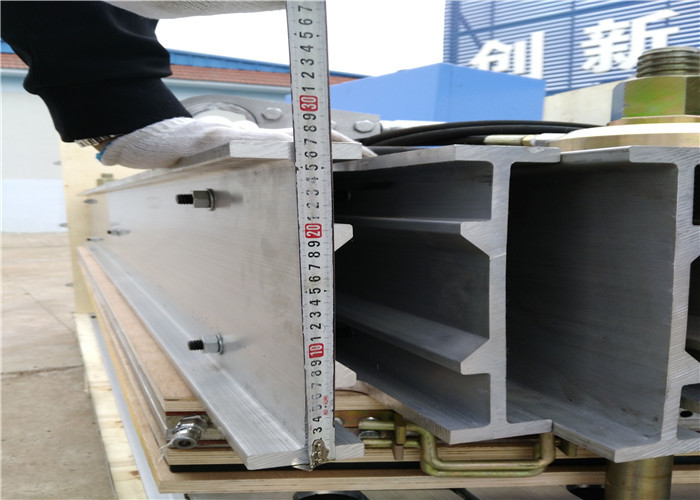

Constructed from high-quality aluminium alloy, the machine boasts a robust yet lightweight frame that combines durability with ease of handling. Aluminium alloy is known for its excellent corrosion resistance and strength-to-weight ratio, making it an ideal material for industrial equipment that must withstand harsh operating environments while remaining manageable for users. This material choice ensures that the mechanical components of the splicer maintain their integrity and performance over extended periods of use.

The Conveyor Belt Vulcanizing Equipment operates within a wide temperature range of 0 to 300°C, providing the versatility needed to accommodate various types of rubber compounds and vulcanizing requirements. This broad temperature range allows the device to be used for different belt materials and thicknesses, ensuring compatibility with a diverse array of conveyor belt types found in industries such as mining, manufacturing, and logistics.

For specific vulcanizing tasks, the equipment maintains a regulated operating temperature between 0 and 200°C, which is optimal for most rubber conveyor belt splicing processes. This temperature control ensures that the vulcanization occurs evenly and thoroughly, preventing damage to the belt and guaranteeing a strong, long-lasting joint. The precise temperature management also contributes to energy efficiency and safety during operation.

Functioning as a Mechanical Conveyor Belt Splicer, this equipment simplifies the complex process of joining conveyor belts by combining mechanical pressure with controlled heat application. This dual-action approach enhances the quality of the splice, reducing the likelihood of belt failure and extending the service life of the conveyor system. The mechanical splicing method is widely preferred in industrial settings due to its reliability and the ease with which it can be performed on-site.

In summary, the Conveyor Belt Vulcanizing Equipment is a highly effective and versatile tool tailored for industrial belt maintenance and repair. Its digital temperature and pressure control system, combined with its portability and durable aluminium alloy construction, make it an ideal choice for professionals seeking dependable and precise vulcanizing solutions. With the capability to operate across a broad temperature range and deliver consistent mechanical splicing performance, this equipment stands out as a premier Rubber Conveyor Belt Vulcanizer and Industrial Belt Vulcanizing Equipment in today’s market.

Features:

-

Product Name: Conveyor Belt Vulcanizing Equipment

-

Temperature Range: 0-300°C

-

Heating Type: Electric Heating Plates

-

Portability: Mobile with Wheels, making it a Portable Belt Vulcanizing Device

-

Control System: Digital Temperature and Pressure Control for precise operation

-

Ideal for use as a Belt Joint Vulcanizing Unit

-

Efficient Conveyor Belt Splicing Machine designed for quick and reliable belt repairs

Technical Parameters:

|

Control System

|

Digital Temperature And Pressure Control

|

|

Portability

|

Mobile With Wheels

|

|

Heating Type

|

Electric Heating Plates

|

|

Temperature Range

|

0-300°C

|

|

Operating Temperature

|

0-200°C

|

|

Material

|

Aluminium Alloy

|

Applications:

The Automatic Conveyor Belt Vulcanizer is an essential piece of equipment designed for the efficient and precise vulcanization of conveyor belts across a wide range of industries. Constructed from high-quality aluminium alloy, this equipment ensures durability and lightweight portability, making it ideal for both stationary and field operations. Its robust build allows it to withstand the demanding environments typically encountered in mining, logistics, manufacturing, and material handling sectors.

One of the key application occasions for the Automatic Conveyor Belt Vulcanizer is in the maintenance and repair of conveyor belts used in heavy-duty industrial settings. Conveyor belts play a crucial role in transporting materials in mining sites, quarries, and large-scale production lines. When these belts suffer wear and tear or damage, quick and reliable vulcanization is necessary to minimize downtime. The Hot Press Conveyor Belt Splicer function of this equipment facilitates seamless bonding of belt ends, ensuring the conveyor system resumes operation promptly and efficiently.

Operating within a temperature range of 0-200℃, the Automatic Conveyor Belt Vulcanizer offers precise control over the vulcanization process. The digital temperature and pressure control system guarantees consistent heat and pressure application, which is vital for achieving high-quality splices that can withstand the rigors of industrial use. This advanced control system also enhances safety and usability, allowing operators to set and monitor parameters with ease.

Portability is another standout feature of this equipment. Equipped with wheels, the Automatic Conveyor Belt Vulcanizer can be easily maneuvered to different locations within a facility or transported to remote sites where conveyor belts require splicing. This mobility reduces the need for disassembling conveyor systems or transporting belts to fixed repair shops, thereby saving time and operational costs.

The electric heating plates integrated into the Hot Press Conveyor Belt Splicer provide uniform heating, which is critical for achieving strong and durable vulcanized joints. This electric heating method is energy-efficient and environmentally friendly compared to traditional heating techniques, making it suitable for modern industrial environments focused on sustainability.

In summary, the Automatic Conveyor Belt Vulcanizer is perfectly suited for a variety of applications and scenarios such as on-site conveyor belt repairs in mining operations, factory maintenance workshops, and logistic hubs. Its aluminium alloy construction ensures strength and portability, while its digital temperature and pressure control system guarantees precision and reliability. The electric heating plates and mobile design further enhance its practicality, making it an indispensable tool for maintaining conveyor belt systems efficiently and effectively.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!